Now it's time to use right set of Software Tools for your Plant Operations

Maintenance

Management

Asset

Management

Document

Management

Work Permit

Remote Monitoring

Prism Software offers everything you need to monitor and maintain your entire facility

Assets

Parts

Work Orders

PM

Work Permit

SOPs

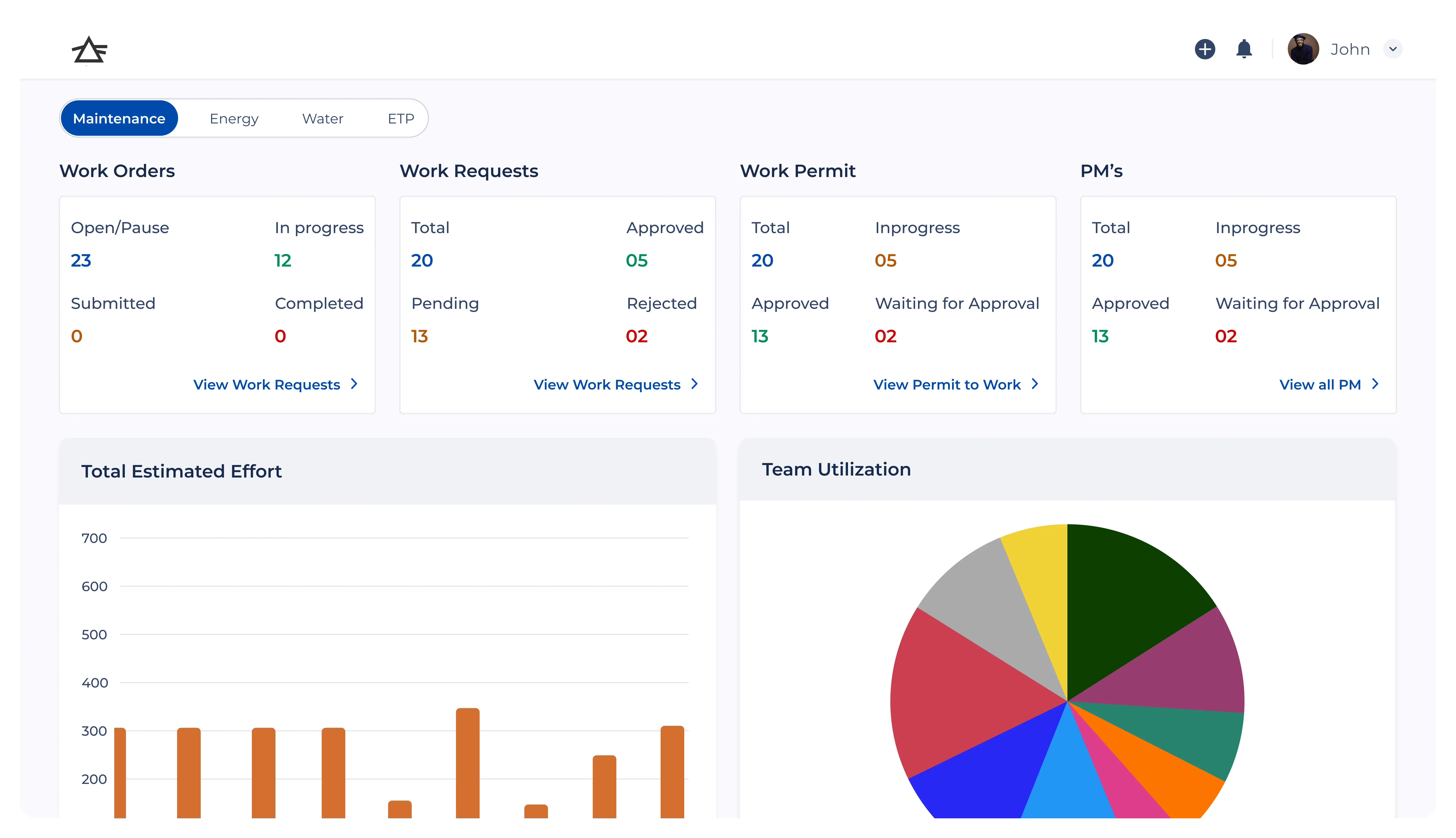

Dashboard

Meters

Documents

IoT

SCADA

Historian

A System that connects everyone for effective collaboration

-

Informed Decisions: Make informed decisions to change your strategy that optimizes the Plant Operations.

-

Performance Monitoring: Analyze operational data and KPIs to improve productivity, reduce costs, and maintain quality standards.

-

Track Team KPI: Keep tracking the Team Performance from result and advice the team improve their efficiency

Easy to use App to Digitize and Automate the Maintenance Operations

-

Comprehensive Asset Tracking: Maintain asset details, maintenance history, and performance metrics for efficient lifecycle management.

-

QR Code Integration: Instance access to asset details via QR Scan.

-

Centralized Document Management: Keep all asset documents in one place for fast and easy reference.

Mobile based Streamlined Breakdown Maintenance Workflow

just focus on what truly matters.

1. Raise a Breakdown Request

2. Accept the Request

3. Complete the Work

4. Review and Approve

IoT based all in one Solution to connect, monitor and control everything in the Plant

-

Live Monitoring & Control: Access real-time data and control remotely via web/mobile SCADA.

-

Any Device, Anywhere: Manage operations on any device for maximum flexibility.

-

User-Friendly Design: Intuitive interface for seamless process visualization and decision-making.